Auf dem Weg zu Effizienz und Innovation

Einleitung

Unser Familienunternehmen mit Sitz in Stadtlohn hat sich auf Maschinen für die Bereiche Umwelt-, Landschaftspflege sowie Landwirtschaft spezialisiert. Wir zählen zu den führenden Anbietern von Frontböschungsmähern. Die Produktpalette umfasst Uni-Mäher, Uni-Seitenmäher, Randstreifenmäher, Böschungsmäher und Mähkombinationen. Hinzu kommen Ast- und Wallheckenschneider, Heckenscheren, Kehrmaschinen sowie Bankettfräsen.

Zu unseren Kunden gehören u. a. Bundesbehörden, Landesbetriebe sowie Gemeinde- und Stadtverwaltungen, Lohnunternehmen und Landwirte. Der Vertrieb erfolgt über ein Netz von Werksvertretungen in Deutschland sowie über die Unimog-Generalvertretungen und Landmaschinenhändler. In Europa bestehen verschiedene Vertriebspartnerschaften. Der Auslandanteil liegt bei 20%.

Das Unternehmen wurde 1904 gegründet und stellte zunächst Heugebläse, Heuwender sowie Getreidemühlen her. Wir beschäftigen aktuell ca. 130 Mitarbeiter und setzen jährlich 35 Mio. Euro um. Die Geschäfte führt heute Herr Christian Dücker mittlerweile in der vierten Generation

Herausforderung

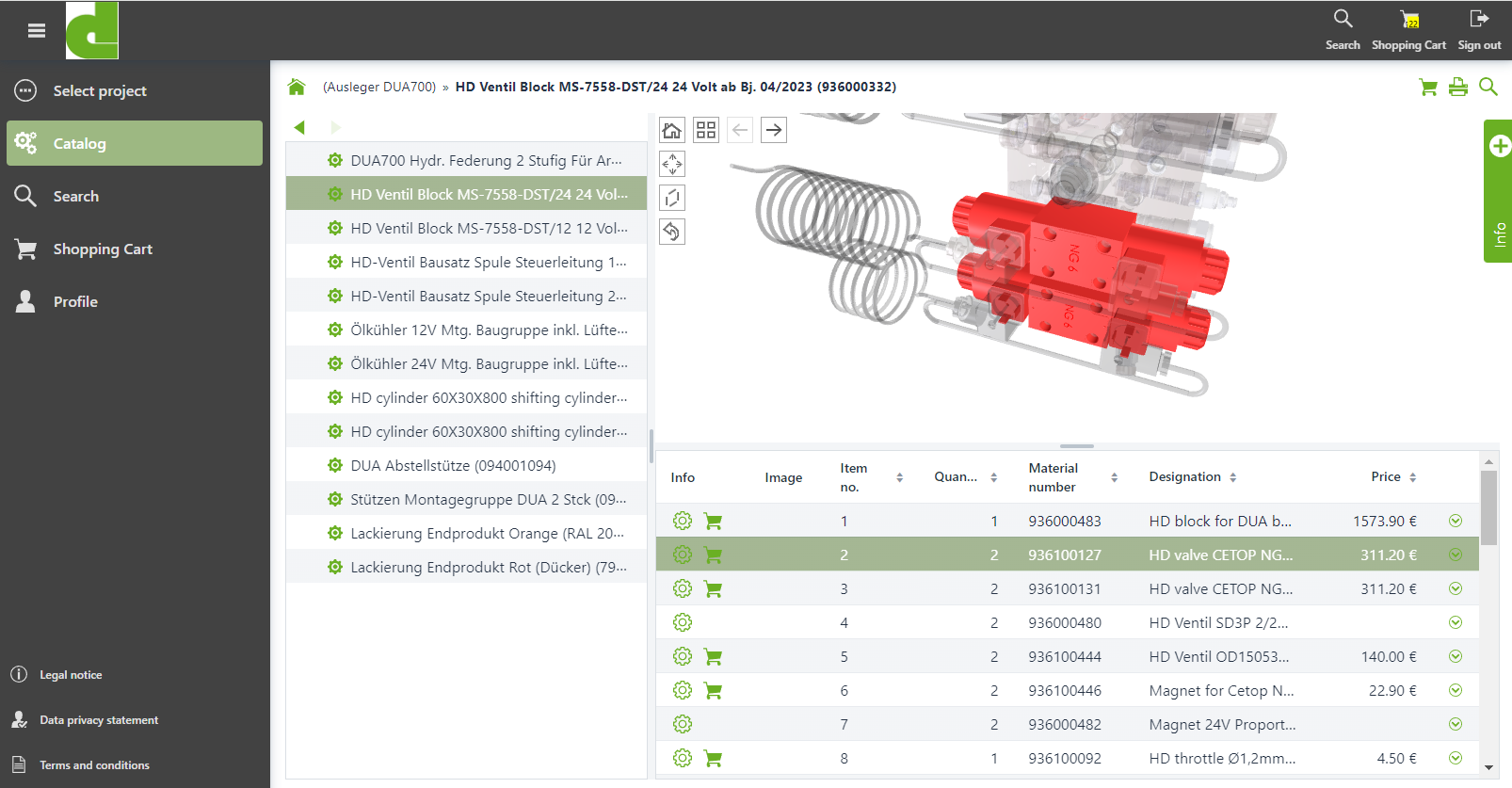

Der elektronische Ersatzteilkatalog, der seit Jahren treue Dienste geleistet hatte, erwies sich als nicht mehr zukunftssicher. Mit einem veralteten System, das nicht mehr den Anforderungen entsprach und keine Möglichkeit zur Online-Publikation bot, war eine Lösung dringend erforderlich. Doch die größte Hürde war nicht nur die technologische Veränderung, sondern auch die Übernahme von Daten aus dem alten System und die Umstellung auf automatisierte Prozesse. Daraus ergaben sich folgende Kernanforderungen, die das neue System auf jeden Fall erfüllen sollte:

- Online-Publikation der Ersatzteilkataloge

- Migration der bestehenden Alt-Kataloge in die neue Lösung

- Weitgehende Automatisierung der Prozesse für Erstellung und Pflege der Daten

- Möglichkeit der Erstellung von seriennummernbezogenen Katalogen und Auswahl des passenden Katalogs über die Eingabe von Seriennummern.

Die Entscheidung

Nach gründlicher Prüfung der verfügbaren Optionen fiel die Wahl auf SpareParts365. Ausschlaggebend für diese Entscheidung waren im Wesentlichen:

- Integrierte Portallösung

- Cloud-Variante als SaaS (Software as a Service) verfügbar

- Keine Investition erforderlich durch Subskriptionmodell

- Geringe Einführungs- und Betriebsaufwände

- Keine doppelte Datenpflege

- Modernes und intuitives „Look & Feel“

- Risikoarmer Einstieg in das Projekt möglich

Diese innovative Softwarelösung versprach nicht nur eine Lösung für die aktuellen Probleme, sondern auch eine zukunftssichere Plattform für das Unternehmen. Von der integrierten Portallösung bis hin zur intuitiven Benutzeroberfläche bot SpareParts365 alles, was Gerhard Dücker GmbH & Co. KG benötigte, um ihren Kunden einen leichten und schnellen Zugang zu ermöglichen.

Die Umsetzung

Nachdem die Entscheidung getroffen war, begann das Unternehmen mit der Umsetzung. Zunächst wurde die Konvertierung der Daten aus dem Bestandssystem durchgeführt und damit ein Online-Katalog bereitgestellt, dessen Inhalt 1:1 dem Alt-Katalog entsprach. Zwischenzeitlich begann bei Dücker die Umstellung der Prozesse für die Datenpflege, so dass erste Testdaten aus dem ERP-System generiert werden konnten. Nachdem die Entscheidung gefallen war keinen internen Aufwand in die Umwandlung von Daten zu stecken, wurde die Entwicklung eines Prä-Prozessors beauftragt, der die vorhandenen Daten aus ERP, Konstruktion und Dokumentation in das Importformat von SpareParts365 konvertierte.

Die Ergebnisse

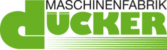

Schließlich war der Moment der Wahrheit gekommen: Der Go-Live von SpareParts365 bei Gerhard Dücker GmbH & Co. KG. Die neuen Möglichkeiten, die sich den Mitarbeitern boten, waren beeindruckend:

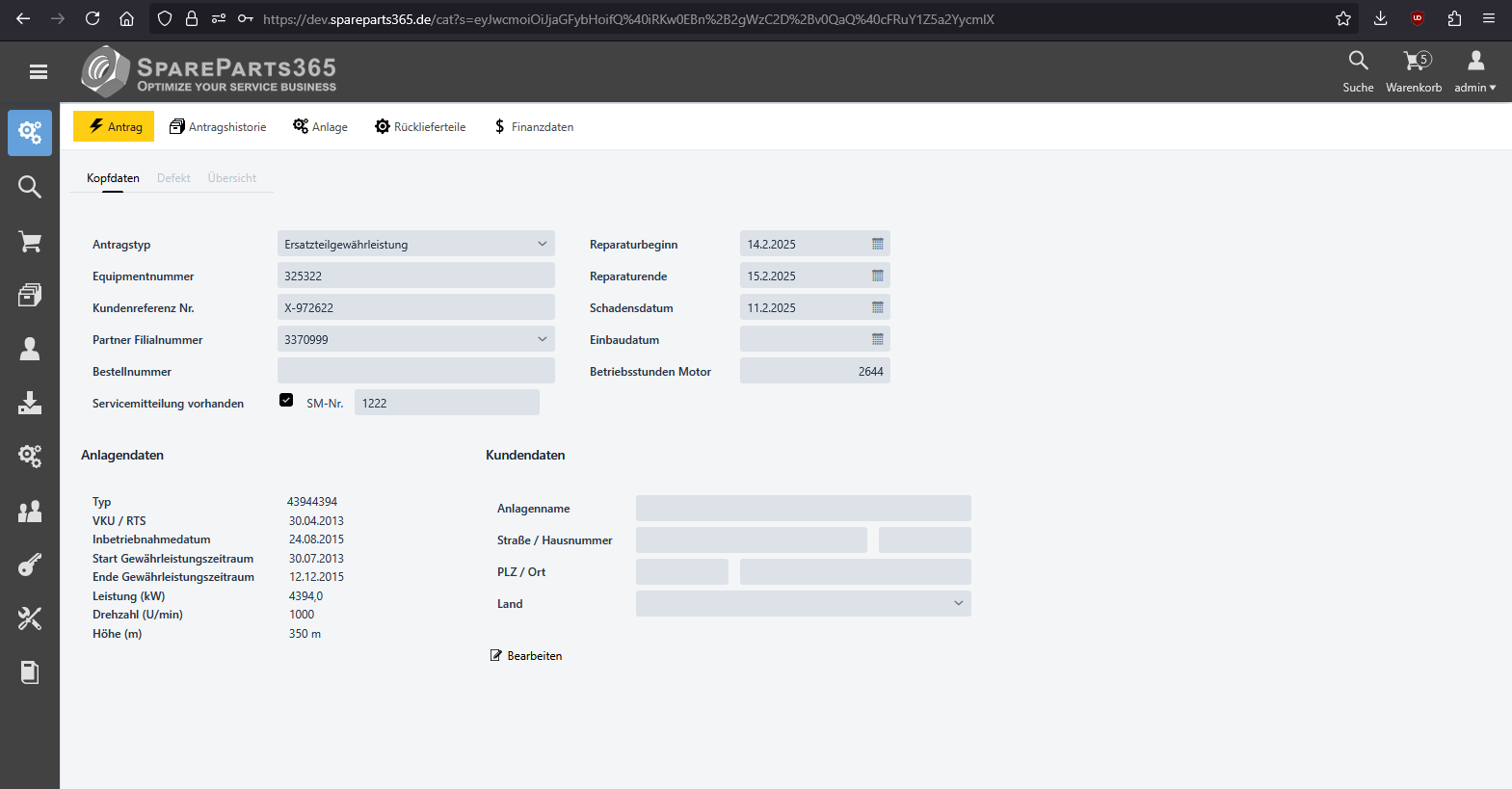

- Auswahl eines Katalogs über eine Produktstruktur oder über die Seriennummer

- Nutzung der neuen, automatisiert erstellten seriennummernbezogenen Kataloge für neu produzierte Geräte, sowie der alten, konvertierten Kataloge für ältere Geräte

- Anzeige von Zusatzdokumenten und Preisinformationen

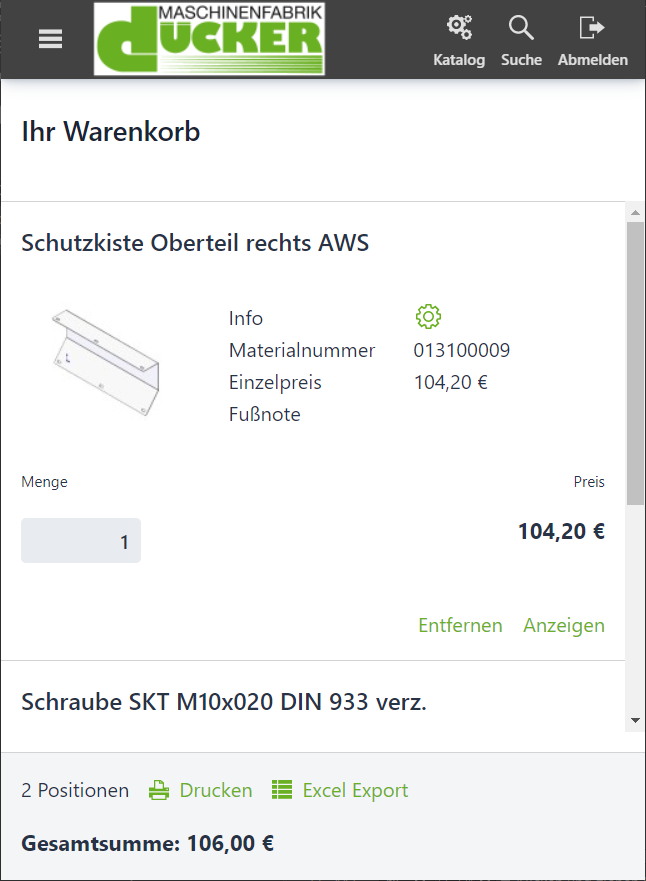

- Sammlung der benötigten Ersatzteile in einem Warenkorb, mit der Möglichkeit über eine vollwertige Shop-Funktion eine E-Mail-Anfrage an den Ersatzteilvertrieb von Dücker zu senden

Von der einfachen Navigation im Katalog, seriennummernbezogene Kataloge, bis hin zur schnellen und fehlerfreien Bestellung von Ersatzteilen – SpareParts365 machte es möglich. Auch Katalogersteller profitieren von einer vereinfachten Datenpflege und automatisierten Prozessen:

- Die Pflege der für den Ersatzteilkatalog erforderlichen Daten erfolgt komplett in proALPHA, Inkonsistenzen und Übertragungsfehler können so vermieden werden.

- Mittels der Produktakten aus proALPHA werden – zusätzlich zu Standardkatalogen für die einzelnen Produkttypen – seriennummernbezogene Kataloge generiert, so dass der Kunde einen Ersatzteilkatalog vorfindet, der genau dem Bauzustand seiner Maschine entspricht.

- Die Aufwände für Katalogerstellung und -pflege konnten so signifikant reduziert werden.

Das Unternehmen war bereit für eine neue Ära der Effizienz und Innovation im Ersatzteilgeschäft.

Das Fazit:

Die Aufgabe, alle benötigten Informationen aus dem Bestandssystem ohne Datenverlust zu übernehmen, erwies sich als herausfordernd, aber mit überschaubarem Aufwand realisierbar.

Die Einrichtung und Konfiguration der Online-Lösung mit SpareParts365 war mit überraschend wenig Aufwand verbunden. Die benötigten Funktionalitäten, um Ersatzteile einfach und fehlerfrei identifizieren und bestellen zu können, sind in der Portallösung SpareParts365 vorhanden und intuitiv zu bedienen.

Der Betrieb des Portals als Cloud-Lösung hat große Vorteile im Vergleich zu einem In-House-Betrieb. Es entfallen sämtliche Aufwände für den Aufbau, den Betrieb und die Pflege einer entsprechenden Infrastruktur, sowie die Notwendigkeit, dafür Know-how aufzubauen und vorzuhalten. Die Nutzung der Subskriptionsvariante von SpareParts365 ermöglichte zudem einen risikolosen Einstieg in das Projekt.

Als interne Herausforderung erwies sich einmal mehr, die erforderlichen Prozesse für die Datenpflege anzupassen und die betroffenen Mitarbeiter erfolgreich einzubinden.

Wie es weiterging:

Nach einer kurzen Testphase mit ausgewählten Werkvertretern im In- und Ausland wurde das Ersatzteilportal unserem Händlernetz allgemein zur Verfügung gestellt.

Zusätzlich hat heute jeder Käufer einer Maschine eingeschränkten Zugriff als Gast auf die Katalogdaten, was sich schnell und einfach über das Berechtigungskonzept mit Rollenmodell von SpareParts365 realisieren ließ.

Aufgrund der intuitiven Bedienung war die Akzeptanz der Nutzer von Anfang an hoch und die Nutzung der Bestellmöglichkeit stieg schnell rasant an.

Dies führte im Ersatzteilvertrieb zu einer spürbaren Entlastung der Mitarbeiter in der Beratung und senkte die Fehlerrate bei der Erfassung der Aufträge um 15%.

Insbesondere Werkstätten unserer Fachhändler schätzen heute die Möglichkeit, die Baugruppen und Maschinen im 3D-Modell betrachten zu können. Dies ist oftmals eine wertvolle Hilfe bei der Identifizierung und Montage von Ersatzteilen.